Crane rollers

LLC “El-Kran" produces wheels for all types of lifting equipment and rollers for rail machinery, so-called "metal rollers" (metal wheels for trolleys, rollers for wagons, including rollers with spline joint, wheels for wagon drying fans, etc.). All products are manufactured in strict compliance with industry standards and have a wide range of practical applications, including international production lines.

Rollers (wheels) for crane load trolleys

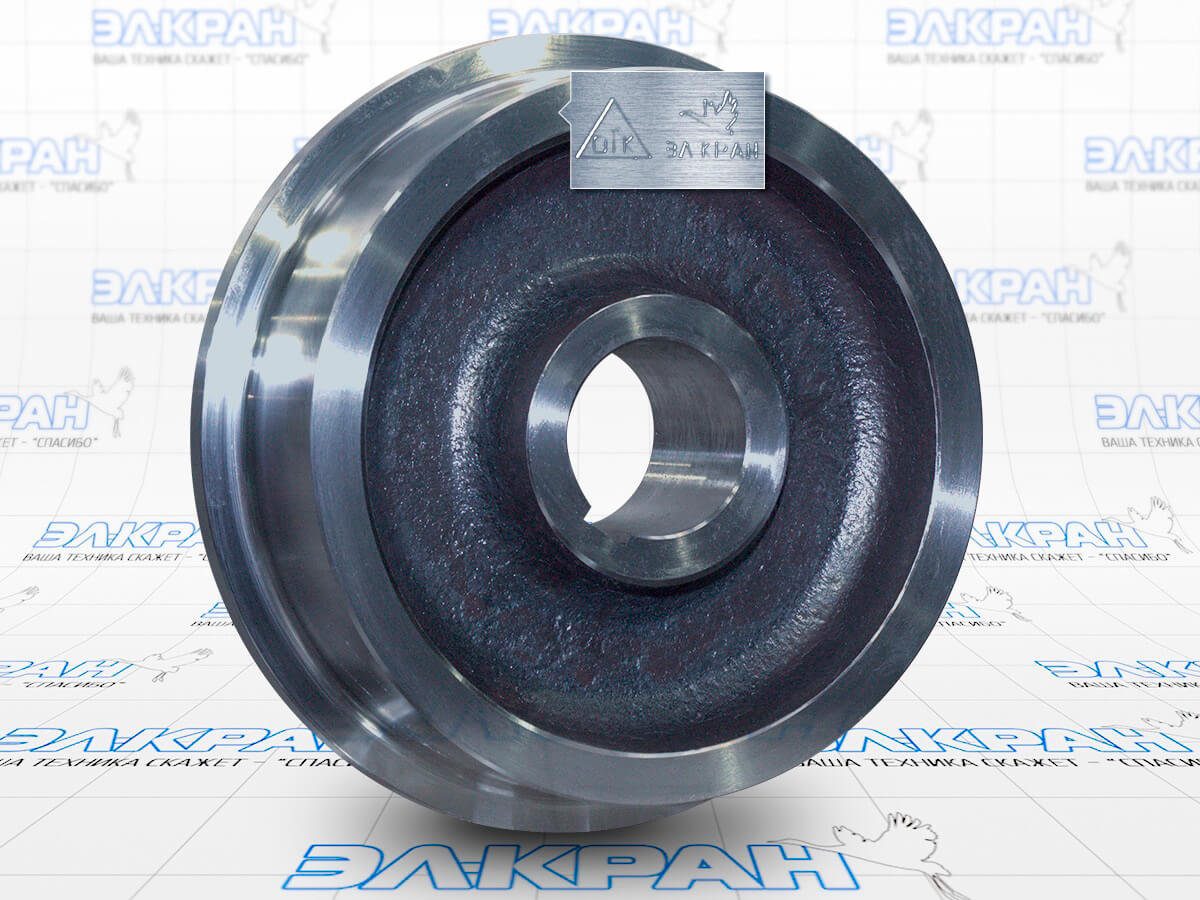

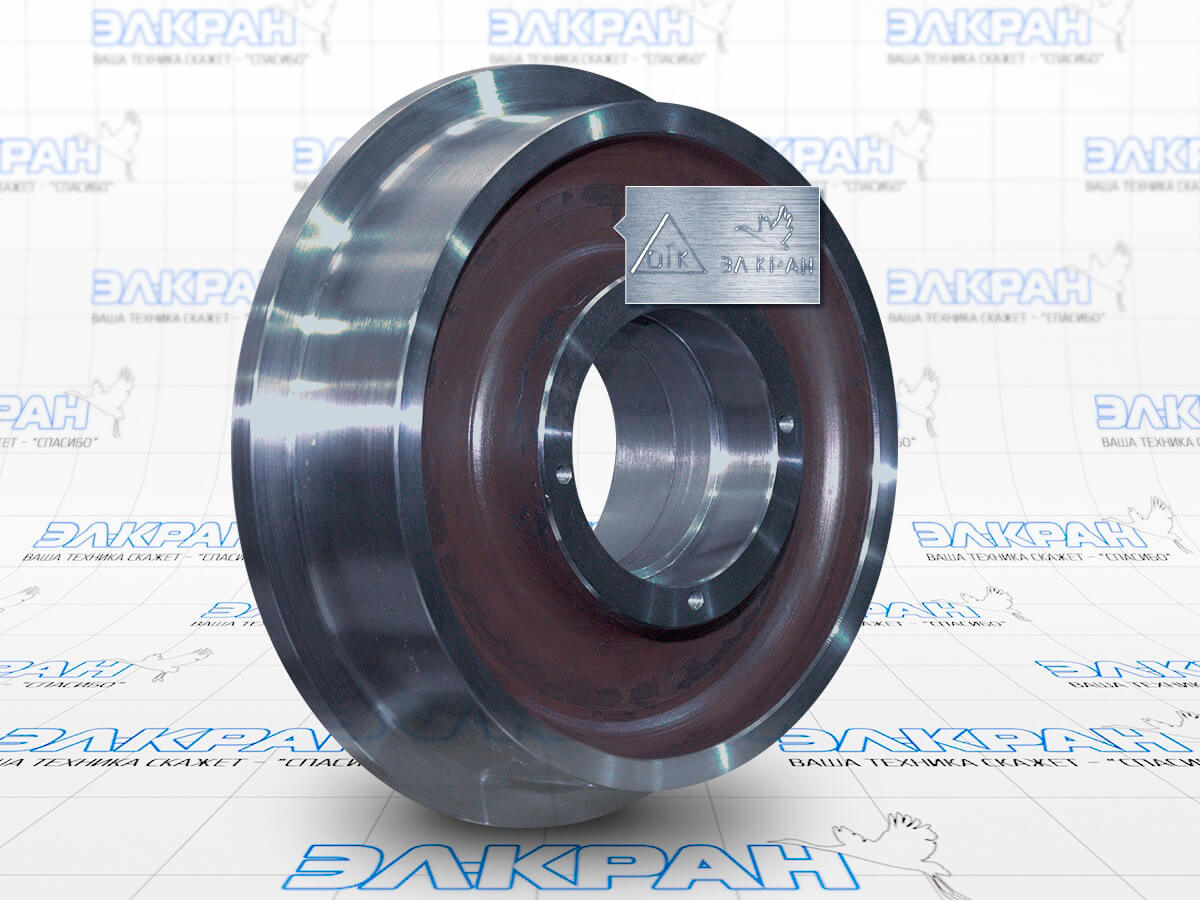

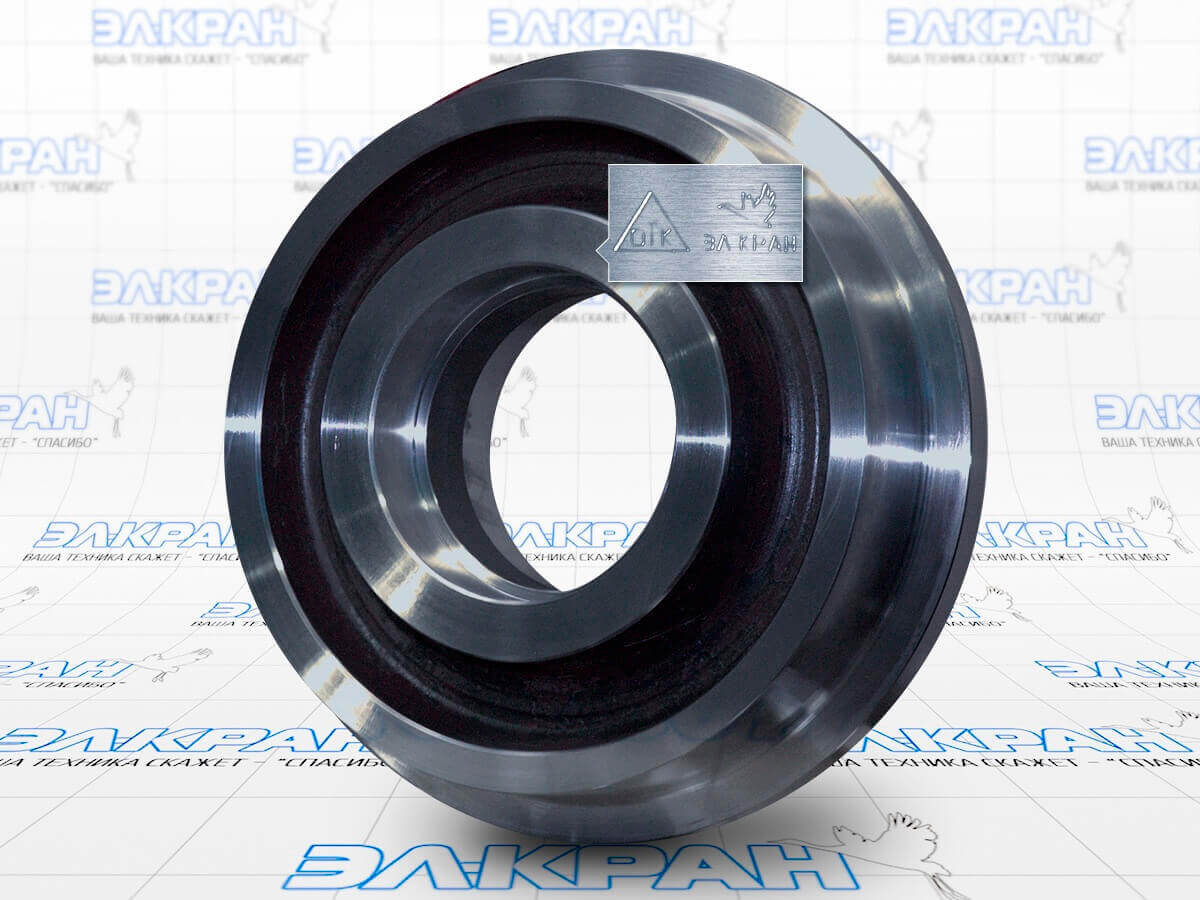

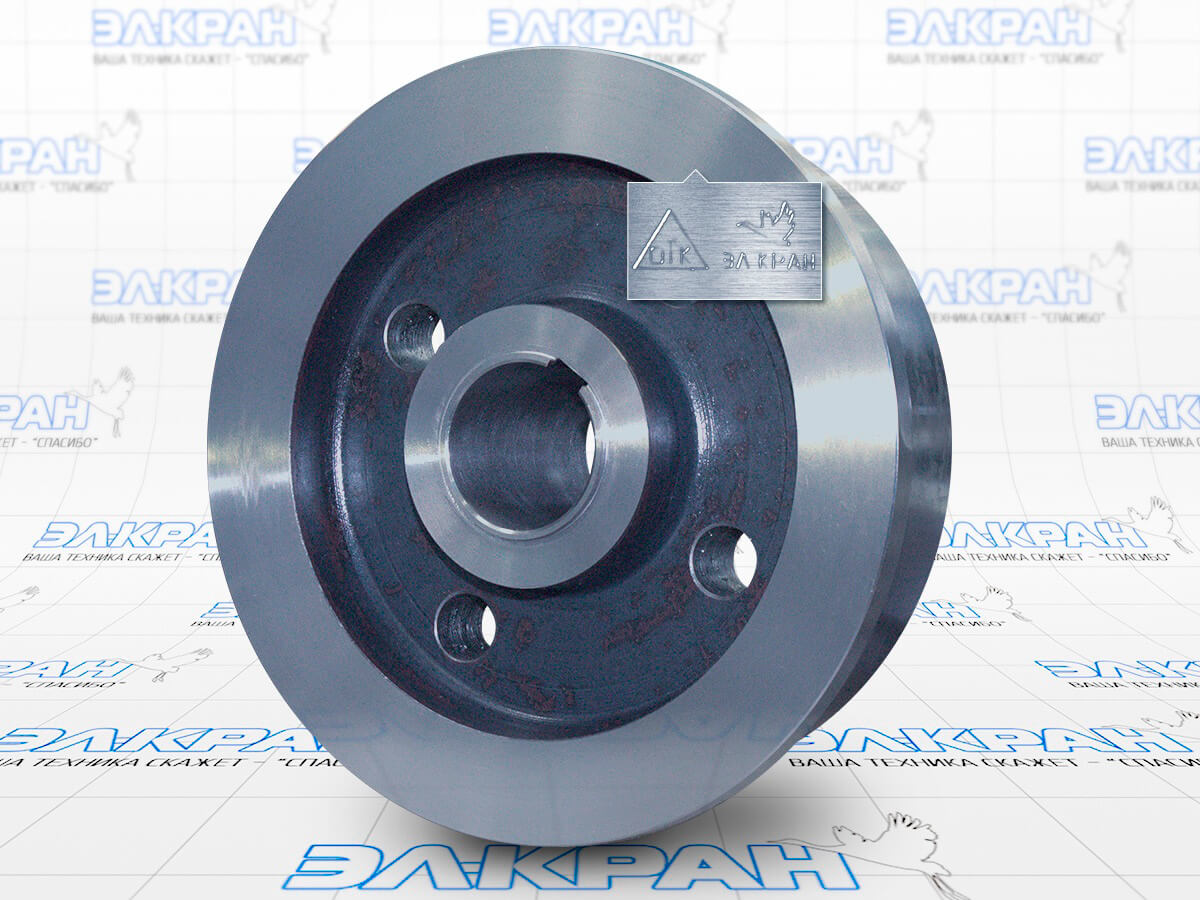

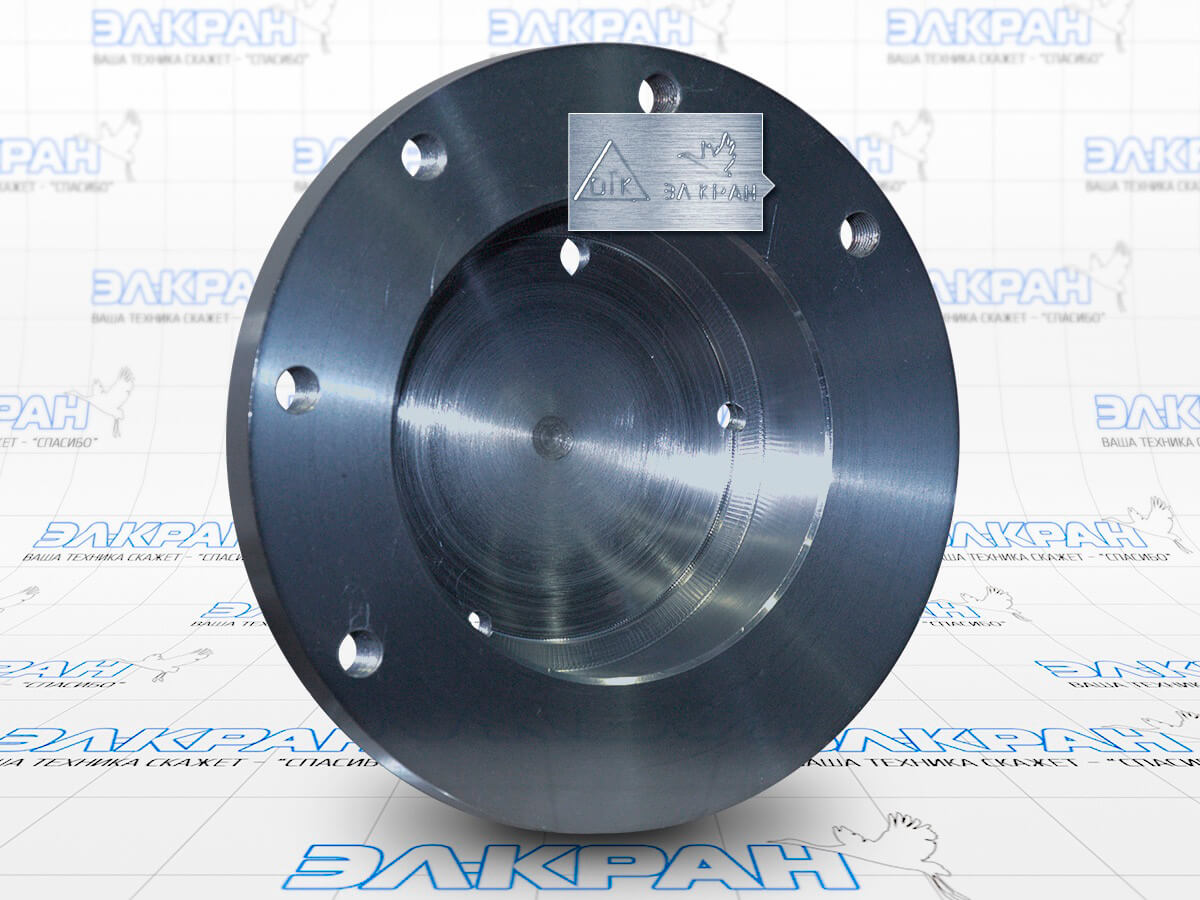

We produce rollers (wheels) for crane load trolleys of all dimension types. The most wide-spread size of the crane trolley wheels is 320/80 К1R (where 320 is the roller diameter, 80 is roller face width). Steel grade 65G or 45, surface hardness 320-360 HB. Heat treatment method - sorbitizing.

Crane load trolley is meant for moving and lifting weights in cranes with a beam arrow, and depending on the crane execution may vary in a design type. In general it is a frame in the bottom of which hoist rope pulleys are fixed, and support wheels, rollers, at the top. Rollers (wheels) of this assignment can be single- or double-flange (К1R and K2R) and no-flange, drive (leading) and idle (driven).

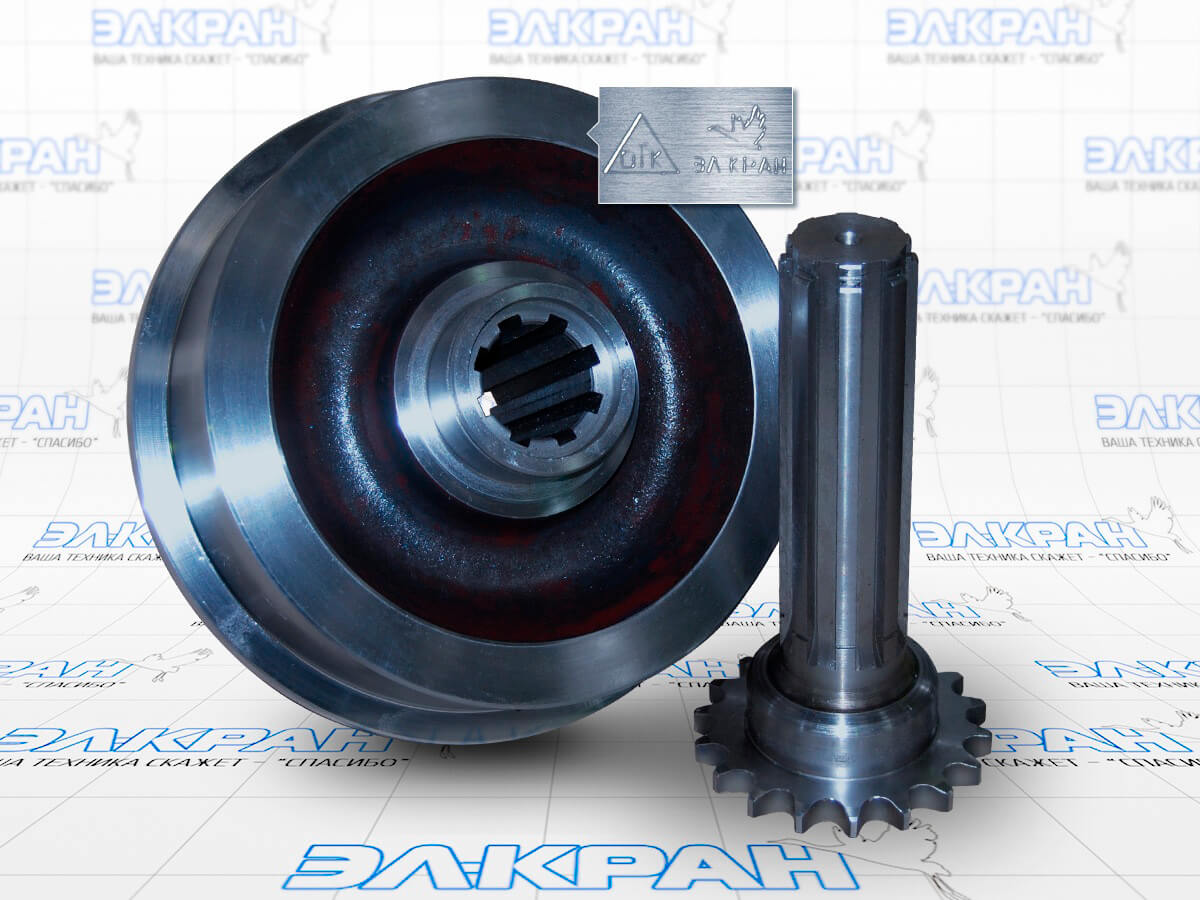

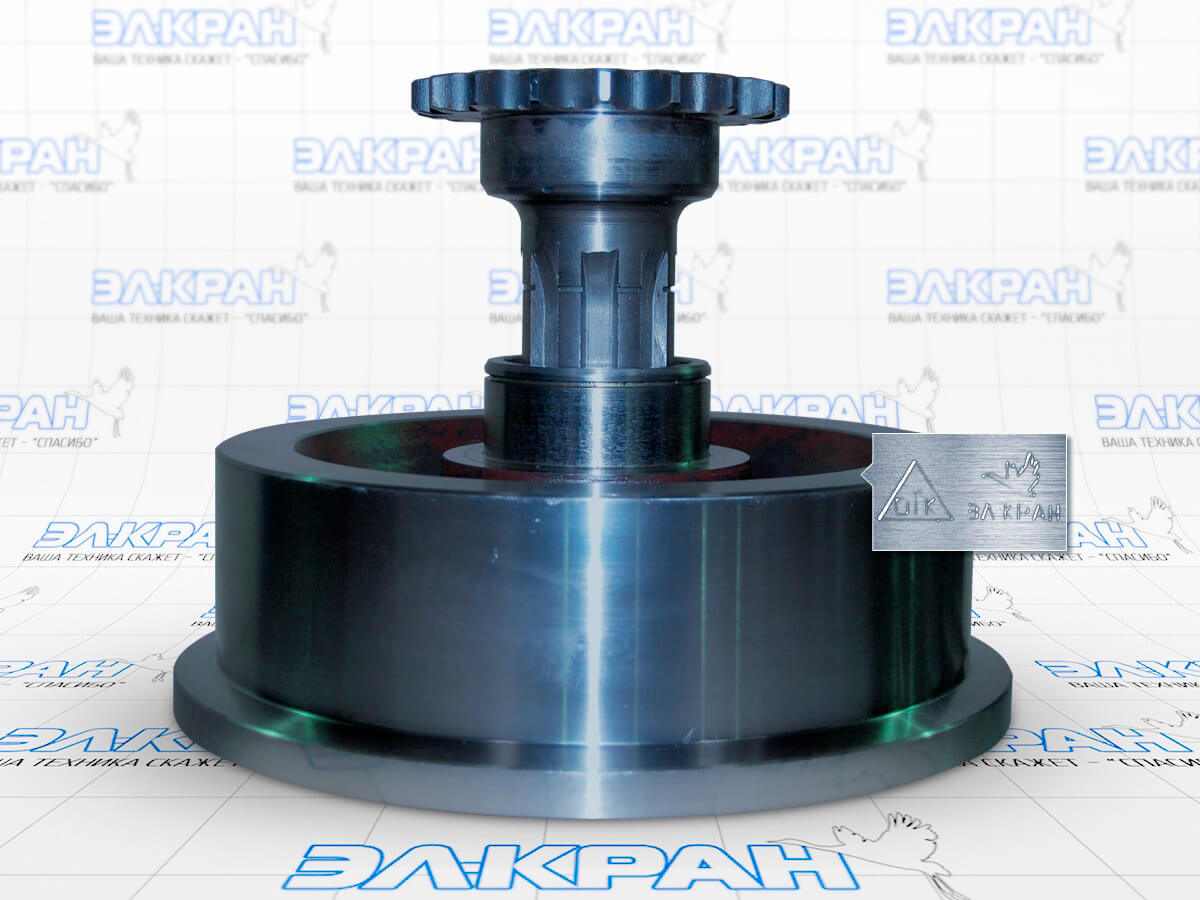

Pictures of rollers (wheels) for crane load trolleys:

Rollers (wheels) for wagons (wheels for kiln wagons, mine wagons and others)

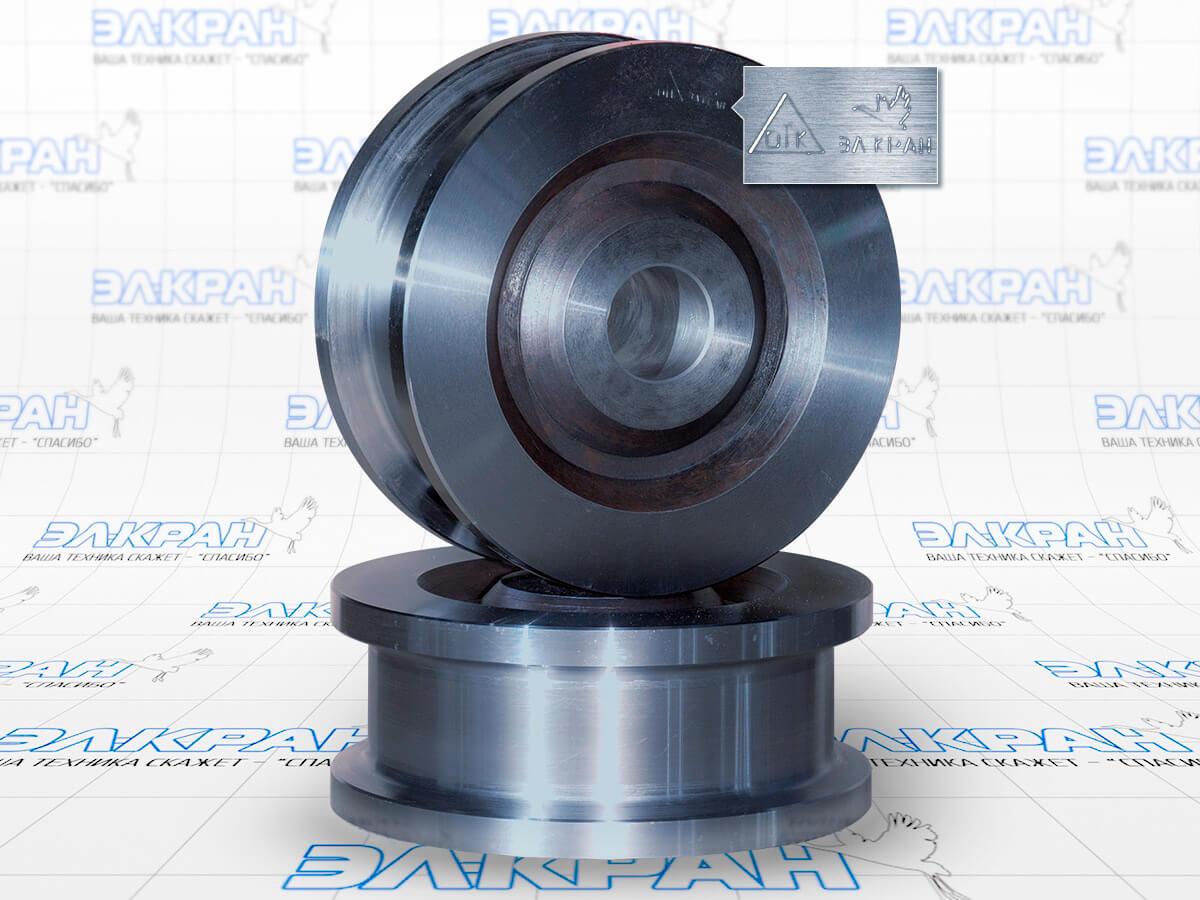

We produce wheels (rollers) for all types of wagons, including special purpose wagons. Our mass production range includes analogue rollers for production lines using splined wheels (rollers) with a shaft such as Wehrhahn (Germany), HESS (Germany), Ceric Technologies (France), NORES (Poland).

Wagon running wheels diameter, depending on a lifting capacity, varies in the range from 290 to 500 mm. Steel grade 65G or 45, tread surface hardness is 320-360 HB. Heat treatment method is sorbitizing. Our own technology of the wheels hardening used in our production is particularly relevant for wagons, operating in challenging temperature conditions (e.g., kiln wagon wheels have a constant temperature difference from 15 to 200 °C).

Pictures of wagon rollers (wheels):

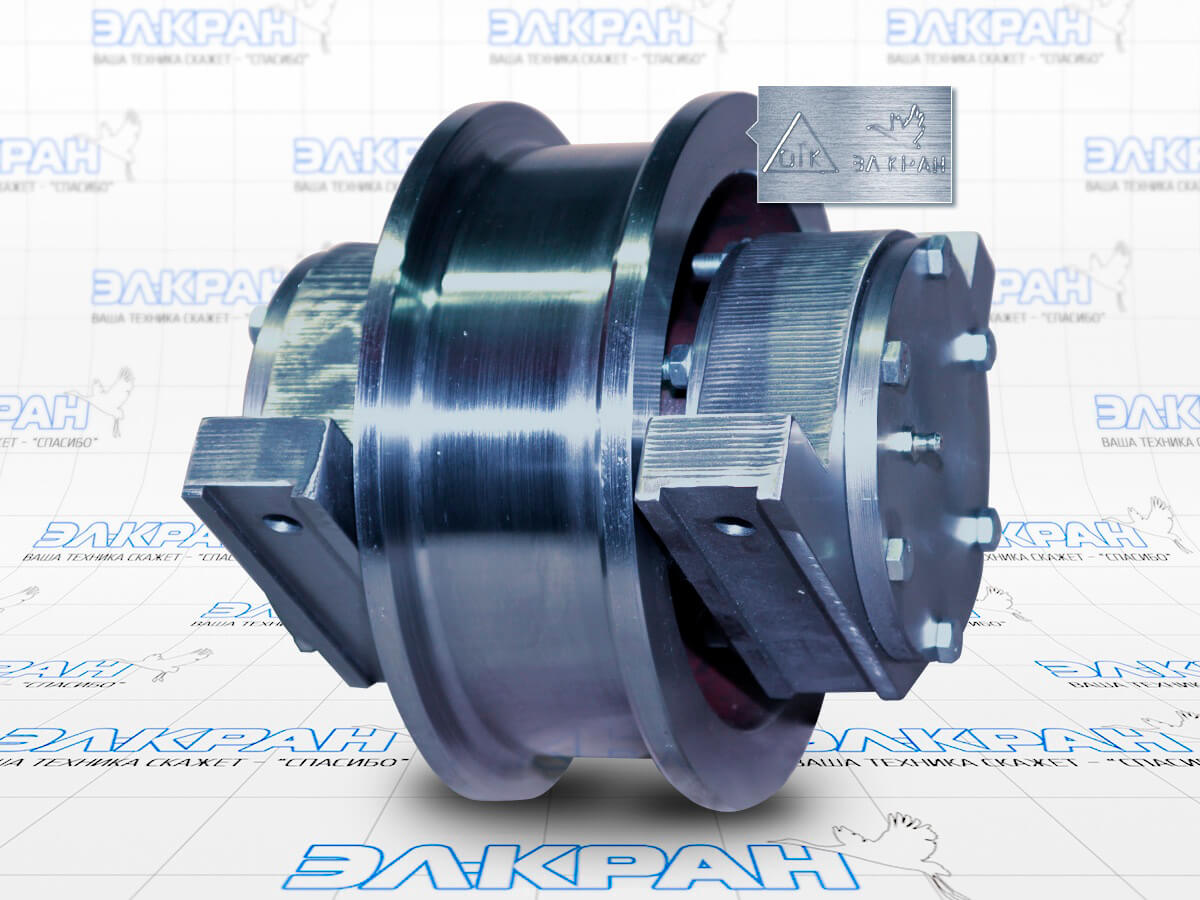

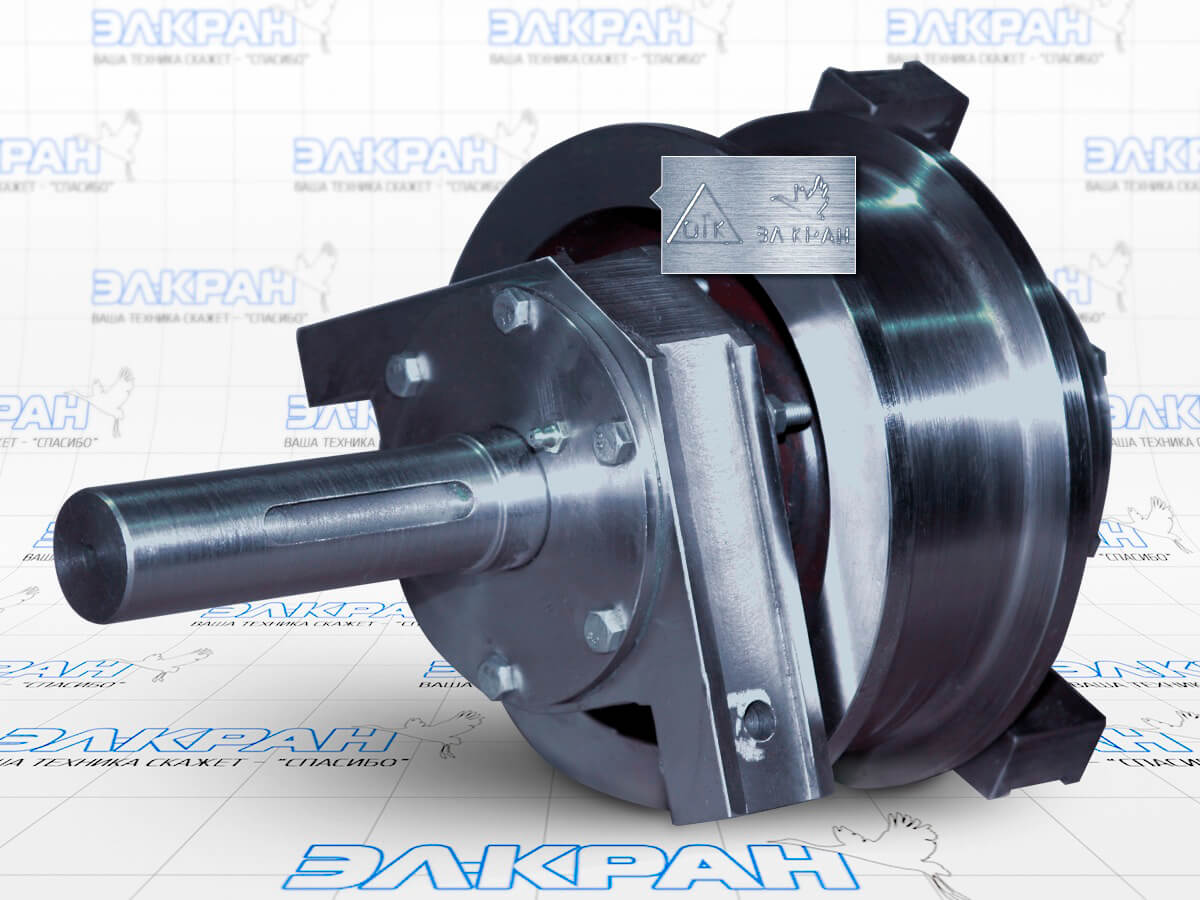

Rollers for transfer rail-guided trolleys

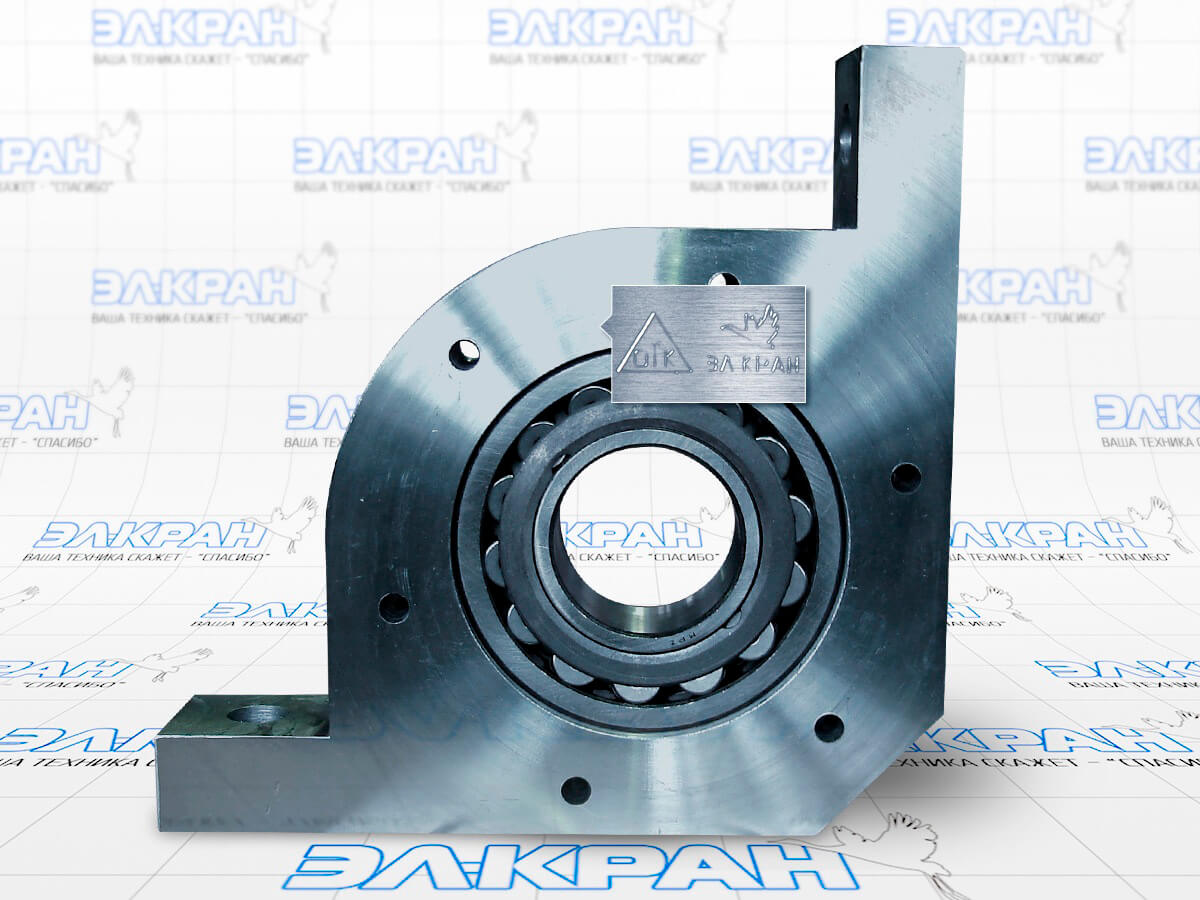

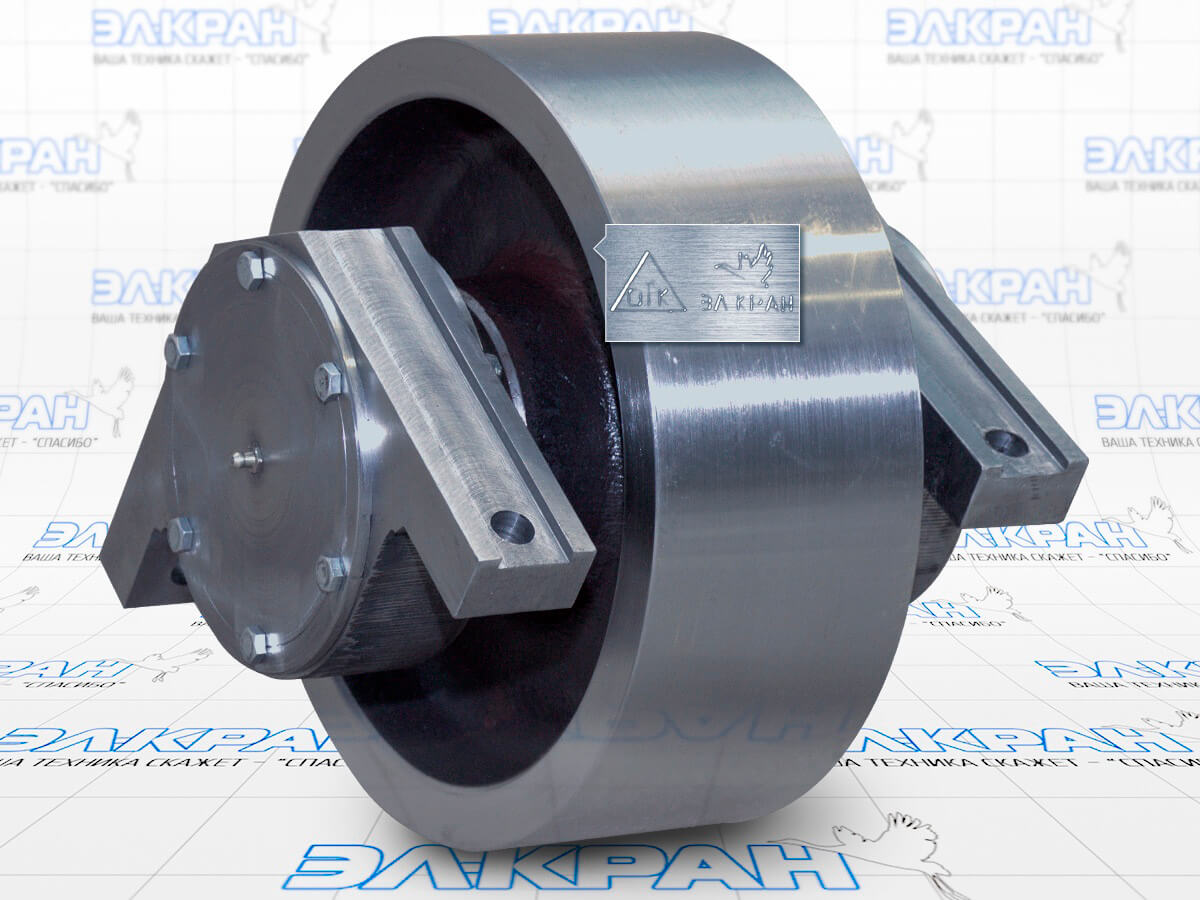

Rollers of transfer rail-guided trolleys structurally have a following distinguishing feature as a transfer rail-guided box. An axle box is a link to connect a wheel pair with the frame and may be of a different execution.

Basic dimension types for rail-guided trolley rollers are К1R 400/105 and К1R 320/100. As well as analog wagon wheels our mass-production range includes rollers K1R for a rail truck Nores and other equipment as a part of international production lines which meet all necessary technological requirements and at more attractive prices than imported spare parts.

Pictures of rollers (wheels) for transfer rail-guided cars:

The level of the industrial and technological capacities of our company allows us to manufacture all types of wheels (rollers) for any rail-mounted equipment at a high level of quality.

Distinctive features of the order execution in our production lines have been over 5 years as follows: fixed terms, flexible pricing, high quality of input components and parts for finished goods production, own wheels manufacturing technology which significantly increases their performance, a complete package of accompanying documents and all the necessary warranties.