KKS-10 spare parts

(spare parts for a self-erecting gantry crane with load capacity up to 10 tons)

It will be correct to say that KKS-10 crane is one of the most popular solutions for open loading and unloading platforms and indoor warehouses. It is chosen for its mobility, compactability, easy installation, operation reliability, relatively not expensive cost. Therefore, spare parts for KKS-10 gantry crane is one of the most important and specific activities of our company.

LLC “El-Kran” specializes in supplies of components for KKS-10 (self-erecting gantry crane with a lifting capacity up to 10 tons). Traditionally, KKS is specific for its Crane motion mechanism, Load lifting mechanism, Load trolley motion mechanism – we are ready to maintain these cranes by supplying spare parts and equipment as single items from our product list same as assembled modifications, providing all the necessary certificates and guarantees.

KKS-10 motion mechanism ensures moving of the beam supports crane on crane ways. High-quality spare parts, their proper installation and timely preventive measures are able to ensure a smooth long term operation of KKS-10 chassis.

In this field of question our company may become your reliable supplier, guaranteeing high quality and flexible price for a number of interchangeable parts (crane wheels, gear couplings, rims, shafts, sheaves and other hardware). Production of many items is possible in 3 days’ time limit.

Below is a schematic diagram, which presents the main components and part numbers of KKS-10 motion mechanism. Each title is supplemented by an internal link, as an option switching you to a specific catalog section of our website, containing comprehensive information on this position and all the necessary technical characteristics.

Scheme 1. Motion mechanism of a gantry self-erecting crane with load capacity up to 10 tons (ККS-10)

-

Reducing gear 1C2Y-200

Reducing gear RCD-350 - Brake wheel d=200 mm drawing (catalogue) number 260.3-19100

- Brake TKG-200

-

Countershaft

Electric motor flange - Gear coupling z=30, m=2,5 drawing (catalogue) number КS.26.00.000

- Electric motor МТF-211-6

- Gear coupling z=40, m=3 drawing (catalogue) number КS.18.01.000

- Drive shaft

- Bearing housing

- Running drive wheel drawing (catalogue) number К12.5.01.04.111

- Gear z=31, m=8 drawing (catalogue) number КS.07.08.004

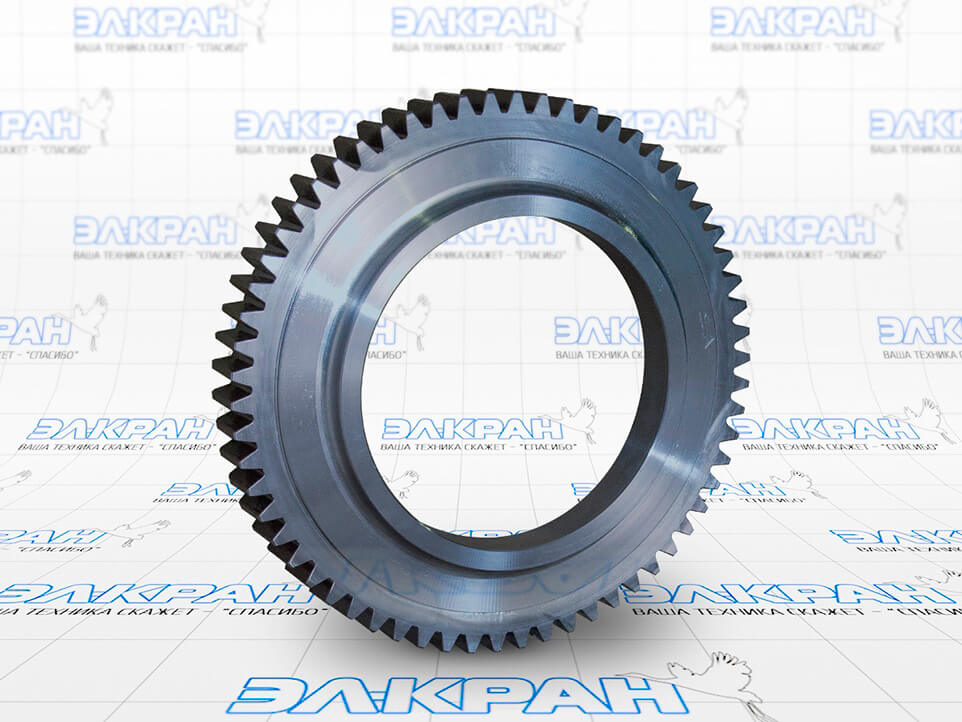

- Gear rim z=62, m=8 drawing (catalogue) number 12.5.01.04.112

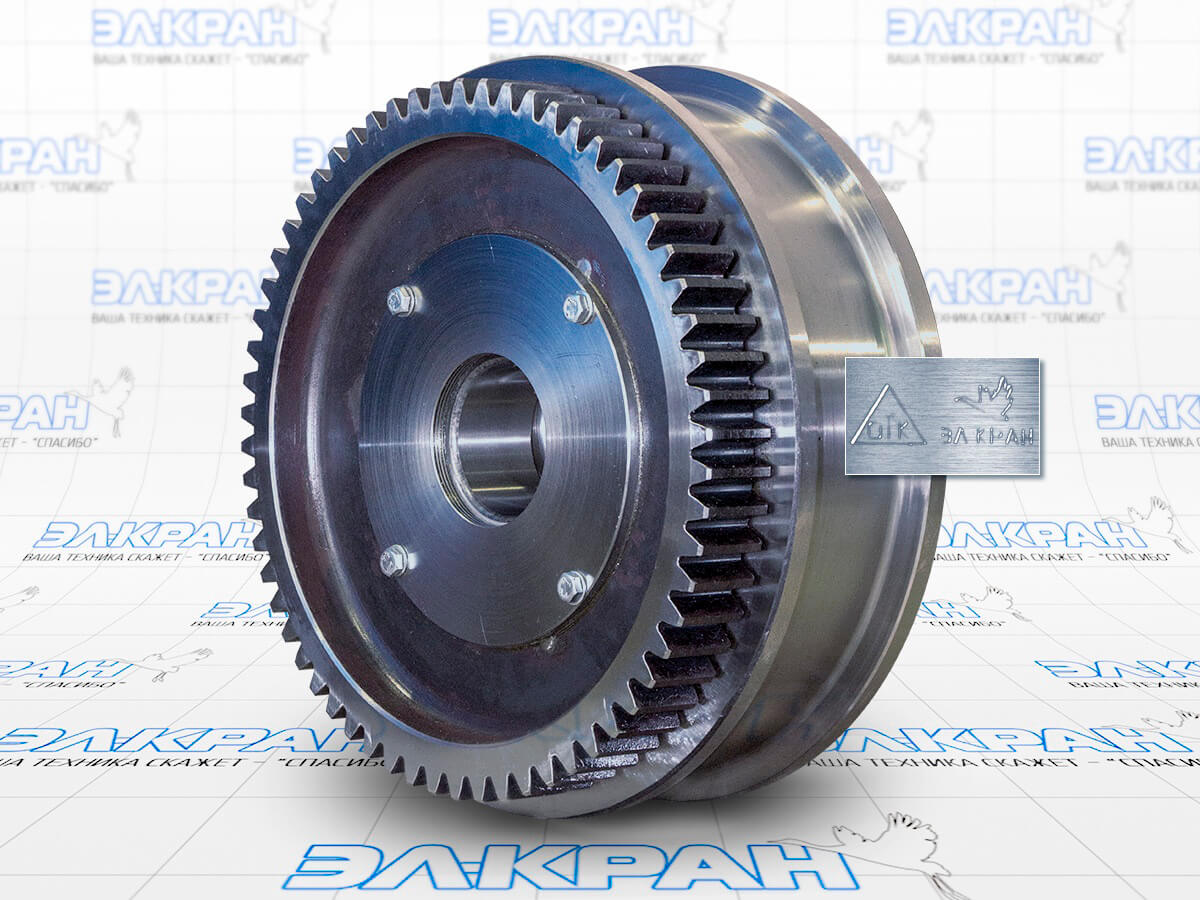

One of the key elements of this process unit are double- flange crane wheels (K2R-500х100) ensuring motion of the crane along the crane ways..

The quality of the wheels and their professional installation directly affects the service life of both the wheels and the crane rail head - extending to several years or shortening to several months.

Crane wheels for KKS-10 produced on our facilities fully meet the challenges of practical operation. Thanks to streamlined manufacturing processes and modern production equipment, some parameters of our crane wheels (for example, accuracy of the depth gradient of hardness reduction at quenching) are stricter than they are required by GOST. Considering this our products are chosen by many Partners from different industry branches and different geographical regions.

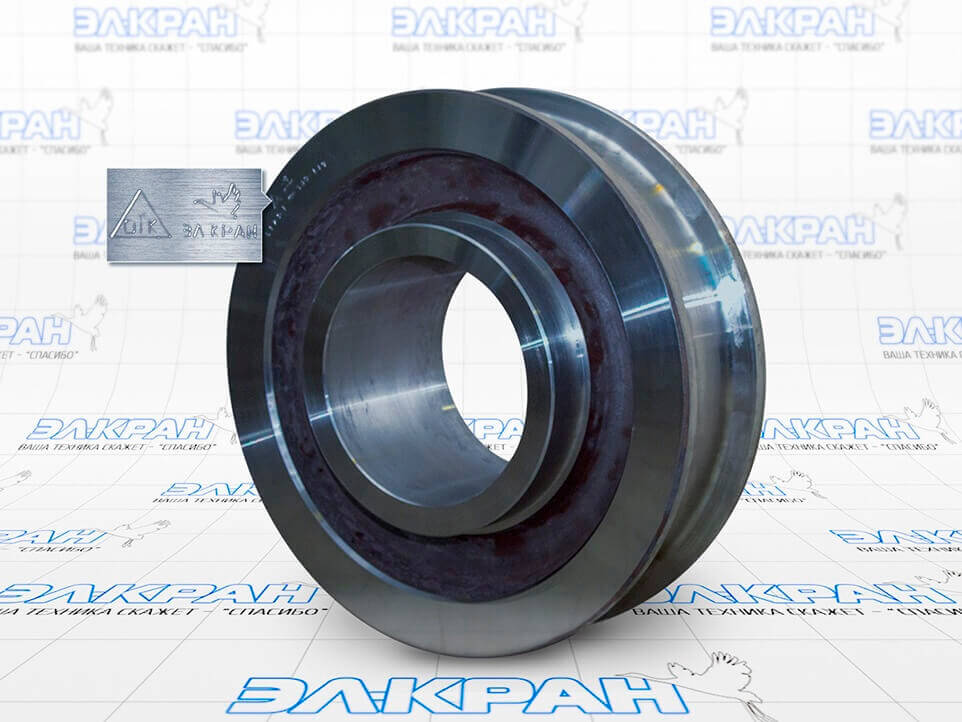

Wheel, drawing (part) number K12.5.01.04.111, shown in Scheme 1, is a double-flange crane wheel KKS-10 crane (K2R - 500х100), manufactured according to GOST 28648-90 from steel stampings (steel grade 65G) (index YA0587). Wheel hardening method in the prescribed hardness range (320-390 HB) is sorbitizing. This wheel can be executed as in the basic performance (idle, drive), and as an assembly with a gear rim.

Crane wheel assembly for KKS-10 (K2R-500х100 SB) consists of a wheel, a gear rim, a lid, a sleeve spacer and a bearing (driving wheel is complemented by the mating gear). Our wheels contain bearings of Minsk bearing plant (JSC "MPZ"). All components are accompanied by certificates, each wheel has a passport and factory markings according to GOST 28648-90.

Below we present the pictures of our product because it is one of the ways to make a preliminary opinion about its quality, but the best way is to come to our production site and see everything with your own eyes.

Thus, double-flange crane wheel for KKS-10 and its components in the most in-demand versions:

Production time of Scheme 1 items is 7 to 14 working days. To order any of the items of "KKS-10 spare parts" category, please give us a call at any of the given phone numbers: 8 (800) 100 33 17 (free for any stationary and mobile numbers), 8 (495) 664 51 17, 8 (4842) 75 10 77 or send a request on our website.

Load lifting mechanism KKS-10

Load lifting mechanism in KKS-10 is one more element of this crane frame which is exposed to intensive wear. Below is its general conventional drawing.

Scheme 2. Load lifting mechanism of a gantry self-erecting crane with load capacity to 10 tons (KKS-10)

-

Reducing gear PM-500

Reducing gear C2-400 -

Brake wheel d=300 mm, drawing (catalogue) number KS.10.00.001

Brake TKG-300 -

Load drum assembly drawing (catalogue) number KS.10.12.000

Flange set - Electric motor МТF-211-6

-

Roller carriage (4)

Roller carriage (2)

Roller d=190 mm drawing (catalogue) number К.12,5.02.05.001 -

Gear coupling z=38, m=2,5 drawing (catalogue) number КС.25.00.000

Electric motor flange

Reducing gear flange -

Spacer shaft

Lifting beam drawing (catalogue) number КС.00.120000Р

Hook 17А with a nut and a bearing drawing (catalogue) number 185,4-17А1

Pulley groove d=360 mm - Load drum hub m=4 z=56 drawing (catalogue) number 145.2-9759

- Bearing housing

The production time for these KKS-10 unit parts will be also 7 to 14 working days.

Motion mechanism of KKS-10 load trolley

Load carriage (trolley) is another dynamic unit of KKS-10 crane that requires close attention to the condition of its parts and equipment.

For this load carriage motion mechanism we produce the following parts: brake wheel, gear coupling, block, load drum hub, load drum assembly. Delivery time is 7 to 14 working days.

Scheme 3. Load trolley motion mechanism of KKS-10 gantry crane with load capacity to 10 tons (ККS-10)

- Reducing gear 1C2Y-200

-

Brake wheel d=200 mm drawing (catalogue) number 260.3-19100

Gear coupling z=30, m=2,5 drawing (catalogue) number KS.26.00.000

Pulley groove d=200 mm; - Brake TKG-200

- Electric motor МТF-211-6

- Load drum hub

- Load drum assembly d=310 mm drawing (catalogue) number КС.10.12.000

- Bearing housing

- Drive shaft

KKS-10, or a gantry crane with load capacity up to 10 tons, is a constructive variation of the a gantry crane, mounted on beam supports (gantries) moving on a rail and crane runways. With proper care of the condition of its units and mechanisms it becomes long-lasting equipment able to operate effectively in heavy workload.